When seconds separate success from disaster, you don’t get to fumble through a disorganized truck bed hunting for the right tool. SWAT and bomb-squad missions operate on a different clock than regular patrol work: there’s no margin for error, no time to improvise, and absolutely zero tolerance for faulty equipment.

It’s about building a platform that moves as fast as your team does, secures gear that could end lives if mishandled, and stands up to the punishment that comes with rapid deployment and rough terrain. Custom SWAT vehicle storage solutions are the difference between “mission complete” and “mission-compromised”.

Mission-Critical Equipment and Why Off-the-Shelf Doesn’t Cut It

Walk through a typical SWAT or bomb-squad loadout, and you’ll understand why generic storage falls apart.

Ballistic shields weighing 40-plus pounds need reinforced mounting that won’t shift during high-speed driving. Entry tools, breaching charges, and explosives-handling gear require secure, separated compartments that meet federal standards. Robot systems come with deployment ramps, remote controls, and battery packs that need quick access without exposing operators to unnecessary risk.

Then there’s the firearms: rifles, shotguns, handguns, and enough ammunition to sustain operations when backup’s 20 minutes out. Throw in specialized PPE, less-lethal equipment, and communication gear, and you’re looking at thousands of pounds of load-critical equipment that needs to be accessible in seconds.

Off-the-shelf storage isn’t up to the job. Weight ratings are guesswork, access points are in the wrong places, and security features can’t handle the demands of transporting firearms and explosives under ATF regulations.

Secure Storage for Firearms and Tactical Gear

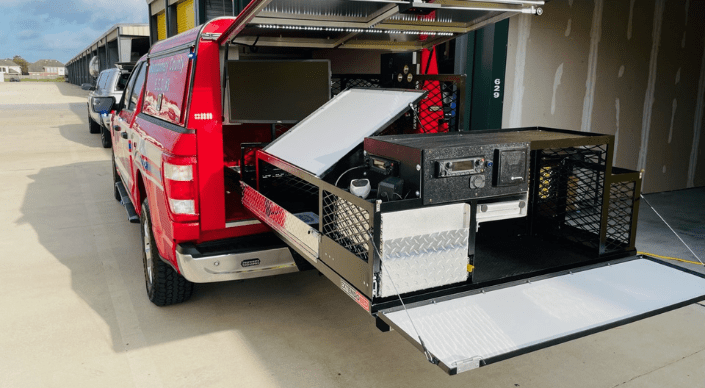

Heavy-duty locking drawers keep long guns, sidearms, and munitions secured during transport and instantly accessible when you hit the ground. Custom compartments sized specifically for ballistic shields, plate carriers, and less-lethal equipment prevent shifting during rapid driving or off-road conditions.

For firearms storage, integrated rifle racks and a gun safe keep weapons separated and protected, with foam inserts custom-cut to each weapon’s profile. The goal isn’t just security, it’s speed. Heavy-duty locking drawers integrate seamlessly with a tactical truck slideout system for maximum accessibility.

When you’re pulling guns from a rack under pressure, every second saved by smart organization is one more second you’re ahead of the problem.

ATF-Compliant Storage for Explosives and Hazardous Materials

For bomb squad trucks, methods for transporting explosives are highly regulated, and for good reason. ATF Type III day boxes meet strict requirements for temporary, attended storage of explosive materials during transit.

These units can be integrated into slideout platforms or built directly into compartmentalized storage, depending on your vehicle type and mission profile.

Key features of an ATF-compliant Type III day box:

- One steel padlock with at least five tumblers and a case-hardened shackle of at least 3/8-inch diameter

- 12-gauge steel construction lined with plywood or Masonite-type hardboard

- Labeled compartments for safe separation of different materials

- Built-in tie-down or mounting brackets to prevent shifting during transport

Slideout Systems and Ramp Integration for Robot Deployment

Bomb-disposal robots are expensive, fragile, and absolutely critical when you’re dealing with suspected IEDs. A tactical truck slideout streamlines robot storage and deployment, bringing the robot to you instead of forcing operators to climb into truck beds or cargo areas under time pressure. Ramp integration allows for fast, controlled offloading in field conditions.

Design considerations matter here: tray length needs to accommodate the robot’s full wheelbase, ramp angle has to be shallow enough for safe deployment, and grip surfaces prevent slipping on wet or muddy ground.

When you’re deploying a $100,000 piece of equipment in a high-stress environment, the last thing you need is a ramp failure or a platform that doesn’t extend far enough.

Supporting On-Site Planning with Built-In Workspace Features

Tactical operations don’t stop when you arrive on scene. They shift into a different phase that requires communication, coordination, real-time decision-making, and a mobile command center. Fold-down tables provide workspace for report writing, mission briefings, or reviewing floor plans while maintaining operational security.

Dry-erase or magnetic command boards mounted inside drawer fronts or on vehicle panels let teams track movements, assignments, and timelines without relying on paper that blows away or gets soaked.

Pull-out shelves give you a stable surface for maps, reference materials, or laptop setups during long deployments.

Matching Configurations to Vehicle Type and Load Capacity

Platform choice matters. Pickup trucks are a natural fit for SWAT team trucks, with slideout beds, like those Extendobed manufactures, delivering weight capacities from 1,200 to 3,000 pounds and over 100% extension for complete bed access. The beauty of a tactical truck slideout is the ability to maximize both horizontal reach and vertical space.

SUVs work well for teams prioritizing vertical space: modular drawer stacks let you build storage upward instead of outward. Vans and box trucks offer the most interior volume for bomb squad trucks or multi-role teams that need large-scale setups with room for robots, disposal equipment, and command infrastructure.

Weight considerations can’t be ignored. Drawer ratings need to match your heaviest gear, axle load limits determine how much total weight your vehicle can safely carry, and ramp strength affects whether you can deploy robots or heavy equipment without structural failure.

Factors to evaluate when choosing your SWAT or bomb-squad vehicle platform:

- Payload capacity: Total weight your vehicle can carry without exceeding GVWR

- Interior vertical clearance: Height available for stacked storage or standing workspace

- Power access and lighting: Electrical infrastructure for charging equipment or operating command systems

- Team size and deployment speed: How many operators need simultaneous access to gear

FAQs

What are the ATF storage requirements for transporting explosives?

The ATF requires explosives being transported to be secured in appropriate magazines. For temporary attended transport, Type III day boxes are commonly used and must be constructed of 12-gauge steel lined with plywood or Masonite-type hardboard, secured with one steel padlock having at least five tumblers and a case-hardened shackle of at least 3/8-inch diameter. Visit the ATF website or contact a legal professional for more information.

How do bomb-squad vehicles safely store and deploy robot systems?

Slideout platforms with integrated ramps provide controlled deployment without requiring operators to lift heavy robots. The platform extends beyond the tailgate, and a shallow-angle ramp with grip surfaces allows the robot to roll safely to the ground. Storage compartments keep batteries, controllers, and accessories organized for rapid setup.

Which custom storage features help maintain readiness during high-stress missions?

Locking drawers for firearms and ammunition, reinforced compartments for shields and entry tools, integrated workspace features like fold-down tables, and quick-access drawer systems that eliminate digging through piles of gear. Every feature focuses on speed, security, and preventing equipment failure under pressure.

Can tactical slideout systems be retrofitted into existing vehicles?

Yes. Extendobed and similar manufacturers offer custom-built slideout systems designed to fit specific vehicle makes and models, including retrofits for existing tactical units. Installation typically involves mounting rails or brackets to the vehicle bed or cargo area, then securing the slideout platform in accordance with weight ratings and deployment requirements.

Do SWAT teams prefer fixed weapon storage or modular configurations?

Most teams favor modular configurations that adapt to changing mission requirements and equipment upgrades. Fixed storage works for departments with standardized loadouts that rarely change, but modular systems with adjustable gun racks, removable dividers, and reconfigurable drawer layouts offer flexibility as gear evolves or mission profiles shift.

Built for Speed, Safety, and Tactical Precision

Here’s the deal: when you’re running hot to a barricaded suspect or responding to a suspected IED, your vehicle either works with you or against you. A well-configured rig makes the difference between hands-on target in 30 seconds and two minutes of being a sitting duck.

If your current setup is costing you time, it’s costing you more than you think. Contact Extendobed, and let’s build something that keeps you ready for the mission.

Recent Posts

- Custom Storage Solutions for SWAT and Bomb‑Squad Vehicles

- Weapon and Evidence Storage for K‑9 Units with Limited Space

- Preparing for Fire Investigations: Organizing Tools and Gear in a Slideout Unit

- How to Outfit a K9 Vehicle For Safety and Efficiency

- Outfitting Mobile Command Centers for Law‑Enforcement Operations

I

I