When you’re managing a group of firefighters, it’s pivotal that you send them in with everything they need. Many lives and a lot of property can be at risk in any incident, and the equipment you carry can make the difference. However, ensuring you have the right equipment on your vehicles and having quick access to it are two different problems, especially considering the speed that firefighters need it. This is why it’s so important that you know how to choose and design a system for fire equipment storage.

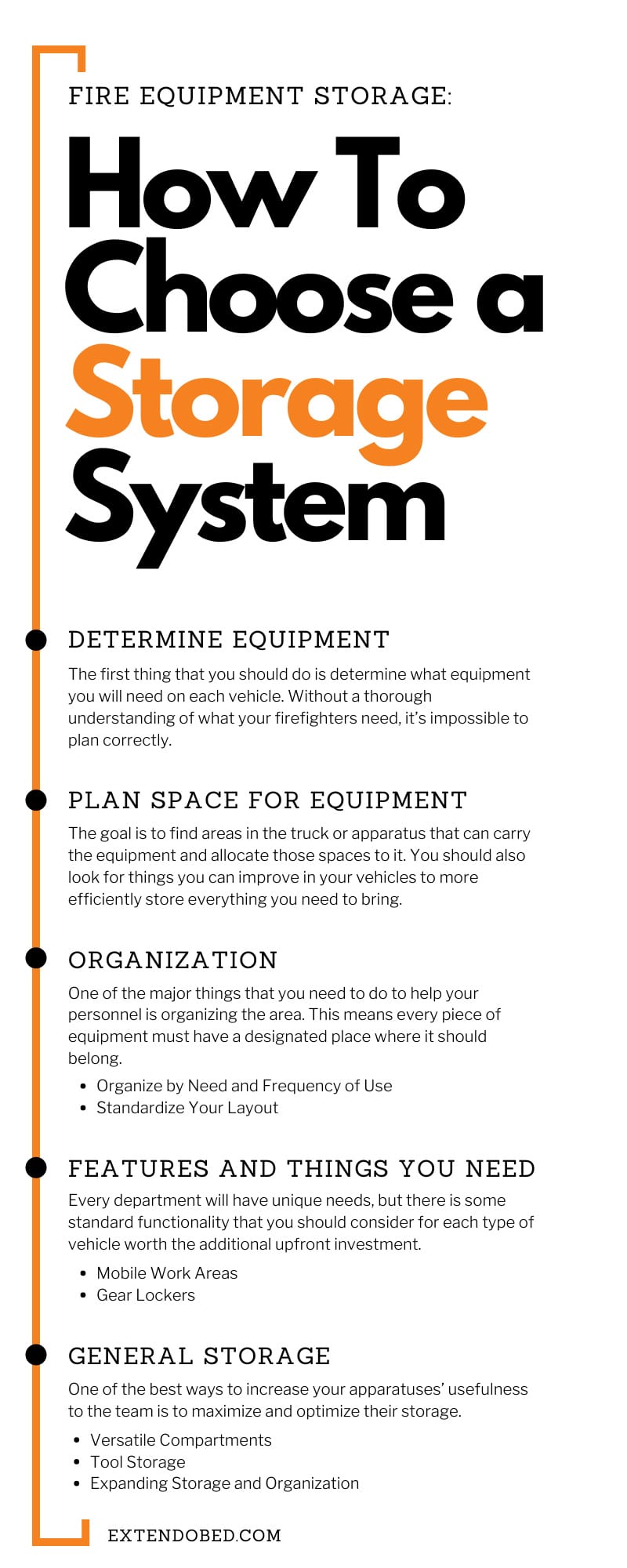

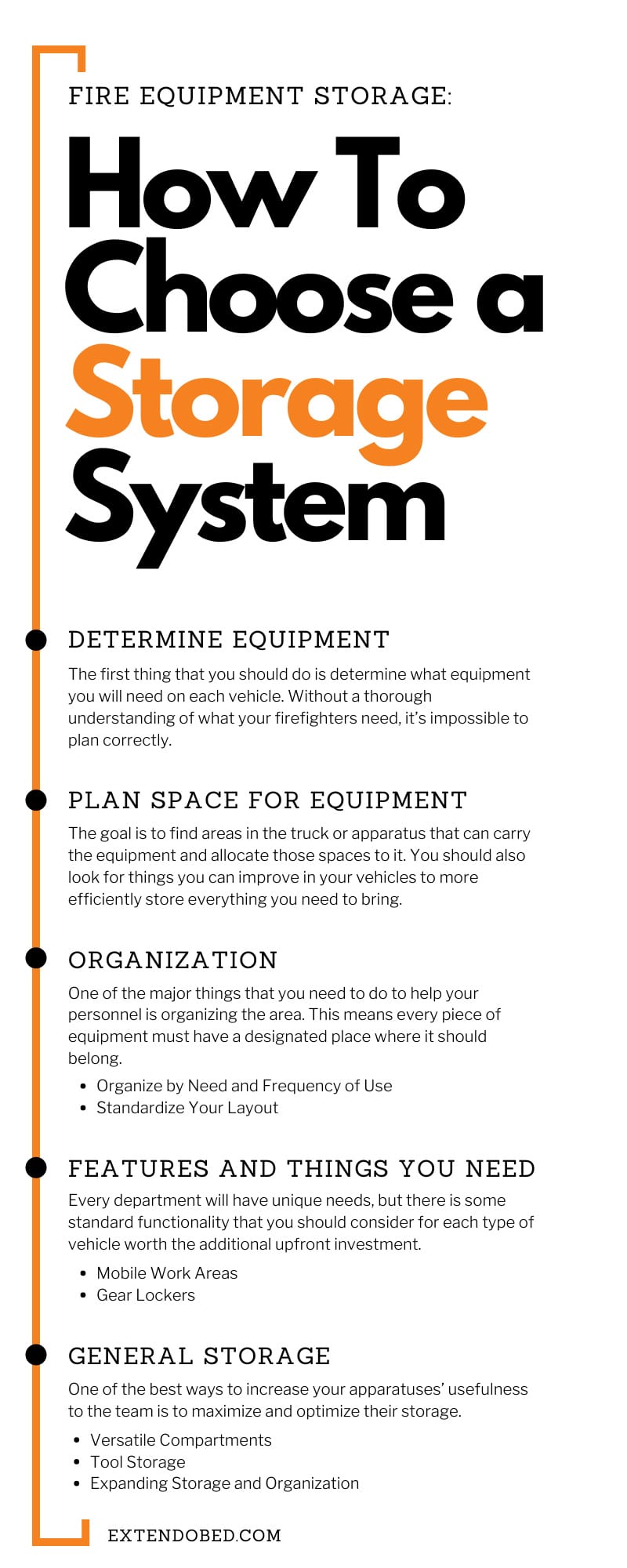

Determine Equipment

The first thing that you should do is determine what equipment you will need on each vehicle. Without a thorough understanding of what your firefighters need, it’s impossible to plan correctly. This is a good time to talk with your crews, as they know best what they require and how often they use different things. Other than them, asking and communicating with your peers in neighboring municipalities will also give you good insight.

Plan Space For Equipment

Once you have a strong understanding of the equipment you will need to carry, plan out the vehicle’s storage space. The goal is to find areas in the truck or apparatus that can carry the equipment and allocate those spaces to it. You should also look for things you can improve in your vehicles to more efficiently store everything you need to bring. Things like aftermarket modifications, which help to add storage or organize space, are good places to start.

Organization

One of the major things that you need to do to help your personnel is organizing the area. Since you’ll be working with different crews and changing personnel, you’ll need to decide what your Standard Operating Procedures will be for how and when to use the equipment. Then, you’ll need to have all personnel follow your SOPs. This means every piece of equipment must have a designated place where it should belong. This way, everyone will know where things are, regardless of shift changes or personnel changes. It’s also important that someone regularly goes through the vehicles to check that all the equipment is there and properly stored.

Organize by Need and Frequency of Use

Arranging all your equipment according to its accessibility and practicality will allow you to get the most out of your organization system. The more useful an equipment piece or tool is, the easier it should be to find. If a piece of equipment that sees frequent use is not easily accessible, it will cause your team to waste time whenever someone goes to use it. For example, it’s beneficial to store frequently used tools closer to the entrances of the truck to lower the amount of time it takes to get to them.

Standardize Your Layout

Once you have a good layout that works for your needs, apply that system to every similar vehicle in your fleet. Having different layouts for similar vehicles performing similar functions can confuse people and waste time. So, you should make sure that everyone knows about your SOPs and your organization system and that every similar vehicle has the same arrangement.

Features and Things You Need

Every department will have unique needs, but there is some standard functionality that you should consider for each type of vehicle knowing it will be worth the additional upfront investment.

Mobile Work Areas

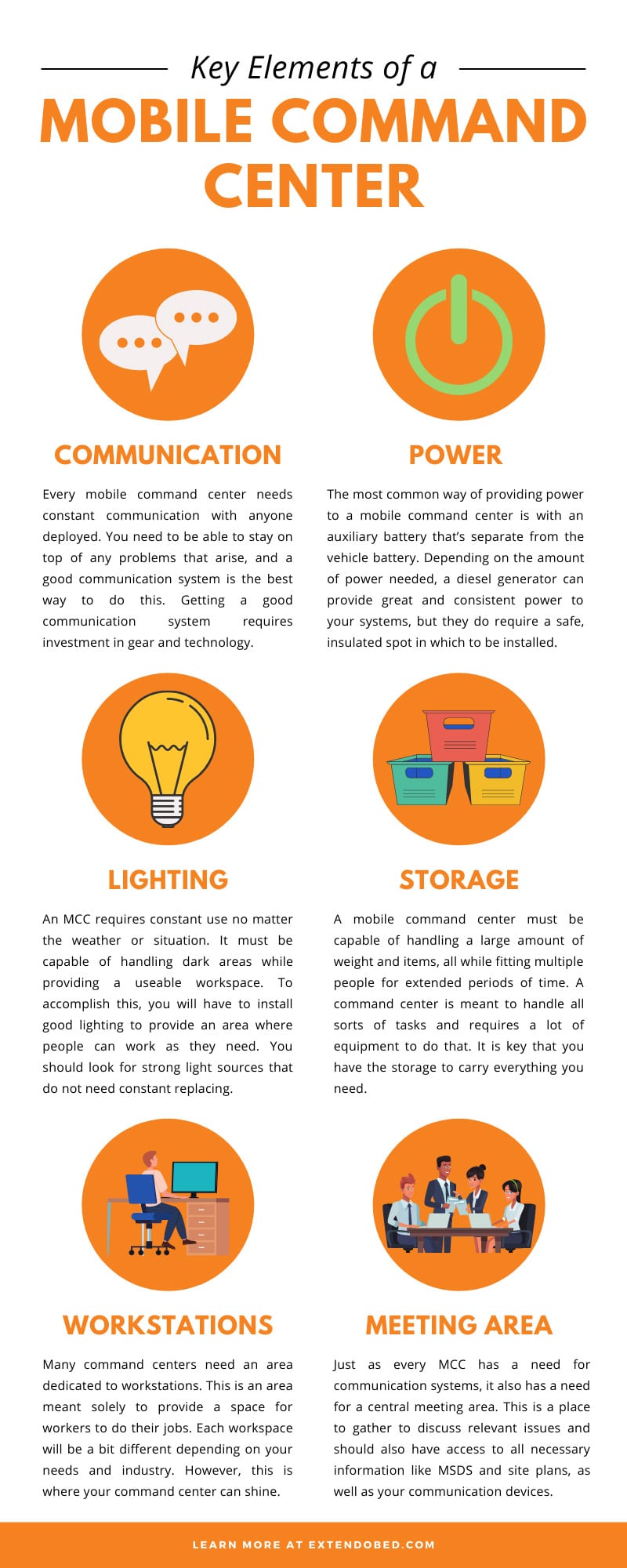

A mobile workspace is a great idea for a lot of different reasons. When you’re on the scene of an incident, you’ll need areas where you can review building designs, MSDS, and other critical information. Having a mobile workplace where you can set up operations can be invaluable.

Gear Lockers

Most stations have gear lockers. A gear locker area on an apparatus can be a good thing for turnouts or other gear. There are plenty of suppliers that provide proper storage for gear on a firetruck.

General Storage

One of the best ways to increase your apparatuses’ usefulness to the team is to maximize and optimize their storage. However, this isn’t as simple as throwing on a few extra storage boxes and calling it a day. To expand and improve the storage of a fire apparatus, you will need to keep these tips in mind.

Versatile Compartments

Adding extra storage through aftermarket modifications is a great plan for carrying equipment. One of the best ways to add this storage is to use compartments that can hold multiple things. Don’t get a compartment only capable of carrying one specific equipment type because the tools you use might change in the future. It’s best to plan for future growth as it’s likely that you will carry more or use different equipment over time.

Tool Storage

There are many storage tricks that you can apply to help efficiently store any tools you have on your vehicles. Utilizing mounting walls is a great place to start, as these items provide storage, organization, and easy tool access. Mounting tools and equipment on vertical walls will make it easy to find and access them.

Expanding Storage and Organization

There are other ways to expand and organize your vehicle storage as well. A good way to do so is to install things like heavy–duty drawer slides for trucks, which give you extra storage and allow you to use your limited space more efficiently. Investing in some truck organizers can save you a ton of room in the firetruck and even help prevent injuries when you’re loading and unloading equipment.

Knowing how to choose or design a storage system for fire equipment storage is an essential skill to have, as laid out here. The extra time a storage system can save is vital to firefighters. Consequently, you need to look for things that will save them the most time. Finding a system that you can customize to your needs is key, as there is no standard for what your firetruck might need. So, keep your options open and plan carefully with your team.